Ultrasound processing of food has become extremely popular in the food businesses. Compared to conventional processing techniques, ultrasonic technology has many benefits, including

- Shorter processing times,

- Higher quality,

- Greater yields,

- increased safety.

In this blog post, we will discuss the benefits, applications, equipment and disadvantages of ultrasound in food processing

Table of Contents

Introduction

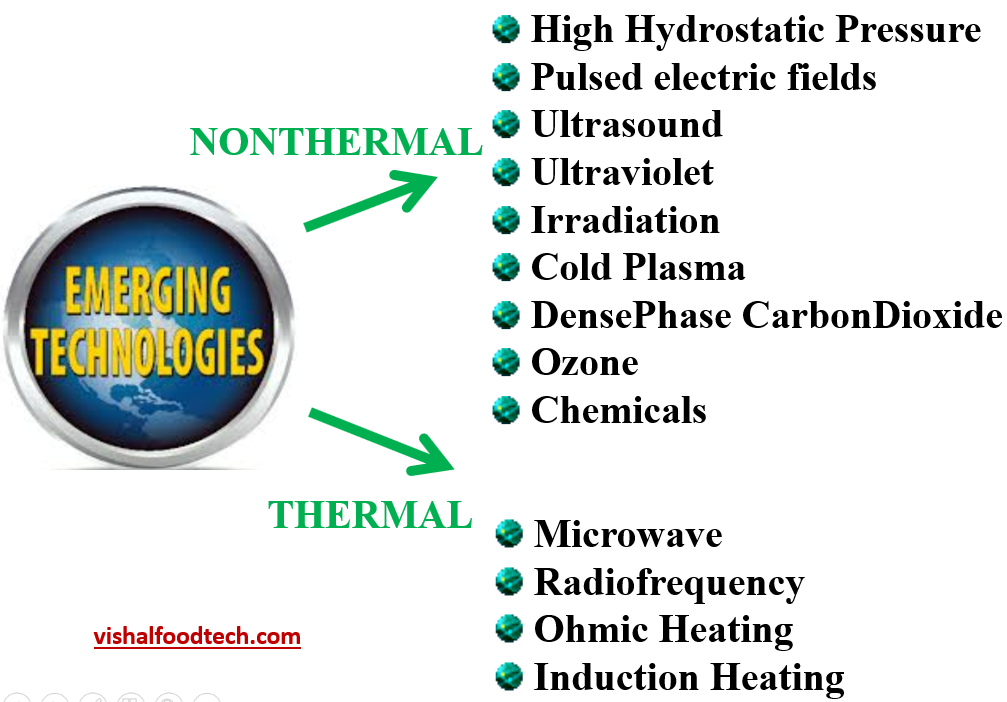

Ultrasound processing is a non-thermal food processing technique that uses high-frequency sound waves to improve food quality, safety, and shelf life.

It is a non-invasive and non-destructive technique that does not changes the nutritional or sensory properties of food products. It has now wide applications in mixing and homogenization, emulsification, dispersion, stabilization, tenderizxation of meat, etc.

What is Ultrasound Technology?

Ultrasound waves have frequency more than 20000Hz, which is just beyond human hearing range. In food processing operations, generally 20kHZ to 10MHz is used.

Human hearing range is between 20Hz to 20000Hz. Where Infrasound is less than 20Hz.

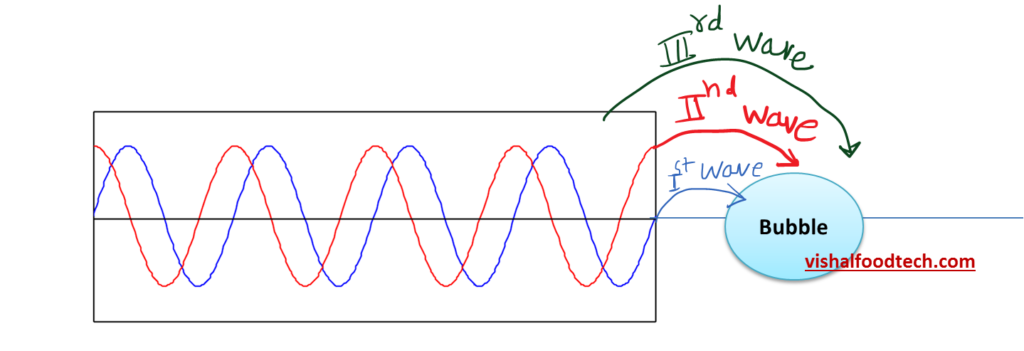

We know sound is an oscillation of particles, either in logitudinal direction ( compression waves) or transverse direction. As we can see in the above figure, kindly note that Ultrasound is a longitudinal wave, in which there is alternative compression and rarefaction of the medium takes place- so pressure varies- resulting energy is transferred to the particles in the medium.

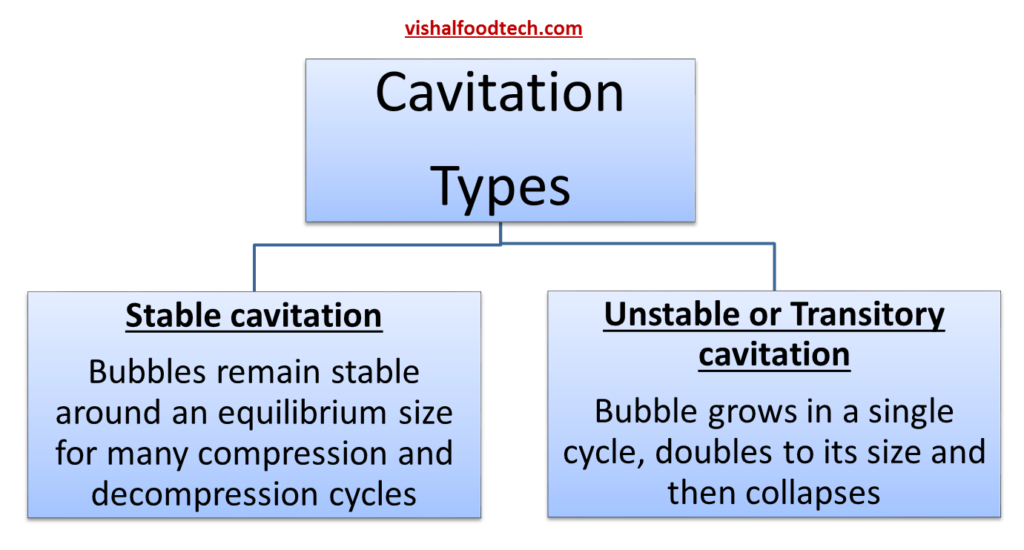

Due to this alternate compression and rarefaction of the medium, cavitation ocuurs leading to bubble formation.

So, within first Depression phase: Bubbles created inside the liquid

Again compression: enormous pressure exerts on the bubble until it implodes and collapses.

In the food industry, ultrasound technology is used to improve food quality, safety, and shelf life. Ultrasound waves are generated by a transducer, which is a device that converts electrical energy into high-frequency sound waves. The waves are then directed towards the food product, where they interact with the food matrix.

Types of Ultrasound Waves

There are two types of ultrasound waves: high-intensity and low-intensity.

High-intensity ultrasound waves are used for the disintegration of food products,

while low-intensity ultrasound waves are used for non-destructive testing of food products.

Ultrasound Equipment Used in Food Processing

The equipment used for ultrasound processing in the food industry contains

The transducer is the device that generates the ultrasound waves, through mechanical vibrations at ultrasonic frequencies, the transducer transforms electrical energy (or mechanical energy) into sound energy.,

Although some transducers types are magnetostrictive, the majority of commercial transducers are piezoelectric. Both cyclic electrical current and changing magnetic fields can be converted into physical vibrations by magnetostrictive devices and piezoelectric transducers, respectively.

while the power supply provides the energy needed to generate the waves.The energy for the system, which is typically an electrical current, comes from the electrical power generator.

The control unit regulates the intensity and frequency of the ultrasound waves. It contains emitters like sonotrodes, horns, etc as discussed below.

Emitters are crucial in ultrasound processing and can take various forms, including baths, horns, or sonotrodes. Unlike emitters, airborne ultrasound systems do not require any physical components. Baths typically consist of a tank equipped with one or more transducers that emit ultrasound waves into the sample.

Horns can be attached to transducers to increase the signal’s strength and apply it directly to the food. Additionally, sonotrodes can be attached to the horn’s tip to further amplify the ultrasonic wave into the sample.

The shape of the horn and the inclusion of a sonotrode determine the degree of amplification. Typically, sonotrodes are made of titanium due to its light mass, allowing for more efficient energy transmission, and high rigidity, ensuring durability. Common sonotrode shapes include knives, nozzles, and dies.

How Does Ultrasound Processing Work?

Ultrasound processing works by applying high-frequency sound waves to food products. The waves penetrate the food matrix and cause vibrations that create small bubbles in the product. The bubbles expand and collapse rapidly, generating heat and pressure that can break down cell walls, destroy microorganisms, and emulsify fats. The effects of ultrasound processing on food products depend on the frequency, intensity, and duration of the ultrasound waves.

More detailed explaination:)

Ultrasound technology is a type of sinusoidal non-ionizing radiation that uses high-frequency sound waves.These high frequency ultrasound waves on hitting the surface of food materials generate a force.

- If the force is perpendicluar to the food surface, compression wave is generated, which moves into the food.

- If the force is parallel to the food surface, a shearing wave is generated, which further moves into the food.

Now when both of these waves sinusoidally enter the food materials, they get attenuated because of the resistance offered by the food materials and vibrations generate bubbles, which continuously form and destroy. Bubbles need continuous energy from waves to sustain themselves otherwise they will collapse.

So we need to continously bombard the bubbles with continuous waves so that they do not collapse.

So from above figure, as the 2nd and the third wave falls on the bubble, there will so much energy that the bubble will collapse and due to this collapse, high temperature of around 1000K and high pressure around 1000atm is generated.

So due to these changes in pressure and temperature high localised heat is generated, which is used for:

- thinning of cell membranes of microbes so that they die because of cell leakage and hence preservation by microbial inactivation takes place.

- free radical procuction which also causes cell death and hence preservation

- breakage of polymeric chains due to shear forces

- to break chemical bonds

Mechanism of Ultrasound processing of food

Applications of Ultrasound in Food Processing

Ultrasound technology has numerous applications in the food industry. It can be used for the following purposes:

Extraction

Ultrasound waves can be used to extract bioactive compounds from food products, such as antioxidants, pigments, and flavors. Ultrasound-assisted extraction is a non-thermal process that helps preserve the nutritional and sensory properties of the extracted compounds.

So If we want to extract oil from mustard seeds, in which, initially no pores are there.

•On treating them with ultrasound, Cavitation Dislodgement phenomenon happens which causes the disruption of the outer layer of the mustard seed.

•So, now more mass transfer takes place and more leaching of oil to outside takes place and hence, more yield by using Ultrasound assisted extraction

Emulsification

Ultrasound waves can be used to emulsify fats and oils present in food products, creating stable and uniform emulsions. This process is faster and more efficient than traditional emulsification methods.

•Ultrasound waves are micro-streamed through milk, due to high shear rate, milk globules of small size are created rapidily.

•Also use of power ultrasound is used in emulsification of fruit juices, tomato ketchup, mayonnaise, milk, etc

Disinfection

Ultrasound technology has the capability to eliminate harmful microorganisms present in food products, ultimately reducing the risk of contamination and increasing their shelf life. This innovative process can be implemented for a variety of food products, whether they are solid or liquid in form.

Tenderization

Ultrasound waves can be used to tenderize meat by breaking down and modifying the connective tissues, producing a more tender and juicy food product.

Preservation

Ultrasound processing can be used to preserve food products by inactivation of enzymes and microorganisms that cause spoilage.

Degassing/ Defoaming

High pressure accoustic waves are used to remove gases from liquids like in coke, excess foam creates, also such as in beer and wine, which improves their quality and taste.

•Many food products require foams presence like in beer, foam is good.

•But in certain food processing techniques, foam is not desired, like in PEF, complete degassing is desired.

•One method is by adding chemicals, which is harmful, so the only method left is to use Ultrasound Processing of food for degassing foams.

•High intensity and high pressure Ultrasound waves on passing through the liquid, foam breaks and some foams are created too. So, a resonance is establish between foam generation and collapse, and ultimately there is no foam.

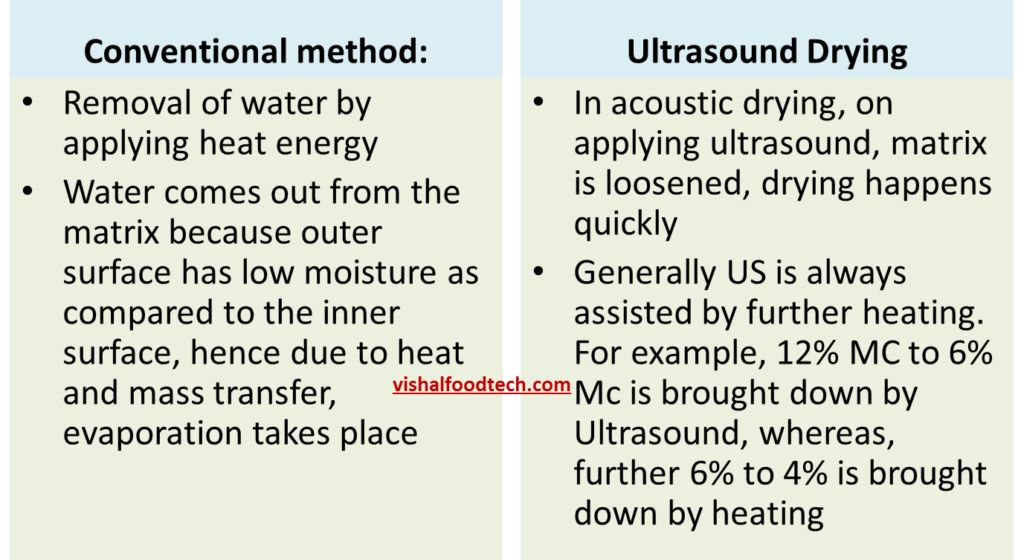

Ultrasound Drying

Ultrasound assisted Crystallisation

•In conventional crystallization, water removes heat for sensible cooling, then phase change happens. So water converts to ice. The nuclei acts as a host for other molecules to come and aggregate together.

•However, when US waves attack the particles, then each particle goes in the excited state and ecan molecule will now acts as a nuclei, hence nucleation increases manifolds and hence extremely rapid crystallization takes place.

Ultrasound assisted Filtration

•Conventional method of filtration is by membrane. However, in ultrasound assisted filtration, there is no problem of membrane fouling.

•Ultrasound waves are bombarded to membranes which contain fouled materials. Due to localized heat generation, bonds of fouling materials are broken and hence clogging decreases. More easy filtration by ultrasound.

Advantages of Ultrasound in Food Processing

Ultrasound processing has numerous benefits over traditional processing methods, including:

Improved Quality

Ultrasound processing can improve the texture, flavor, color, and nutritional value of food products. It can also reduce the formation of off-flavors and off-odors.

Increased Yields

Ultrasound processing can increase yields by extracting more compounds from food products and reducing waste.

Enhanced Safety

Ultrasound processing can reduce the risk of contamination and foodborne illnesses by destroying harmful microorganisms.

Reduced Processing Time

Ultrasound processing is faster than traditional processing methods, reducing processing time and increasing productivity.

Cost-Effective

Ultrasound processing can be cost-effective in the long run by reducing waste, increasing yields, and improving product quality.

Disadvantages of Ultrasound in Food Processing

Despite its many benefits, ultrasound processing also has some challenges that need to be addressed. These challenges include:

High equipment Cost

The cost of ultrasound equipment can be high, making it difficult for small and medium-sized businesses to adopt the technology.

Less Understanding of the Technology

There is still limited understanding of the effects of ultrasound on food products, and more research is needed to fully understand the technology.

Complex

Ultrasound processing can be complex, requiring specialized equipment and trained personnel to operate.

Future of Ultrasound Processing in Food Industry

The use of ultrasound technology in the food industry is expected to grow manifolds in the coming years. Advances in technology and equipment will make it more accessible and cost-effective for food businesses of all sizes. However, more research is also needed to fully understand the effects of ultrasound on food products and to optimize the processing parameters for different food types.

Conclusion

Ultrasound processing is a non-thermal food processing technique that uses high-frequency sound waves to improve food quality, safety, and shelf life. The technology has numerous applications in the food industry, including extraction, emulsification, disinfection, tenderization, preservation, and degassing. Ultrasound processing has many benefits over traditional processing methods, such as improved quality, increased yields, enhanced safety, reduced processing time, and cost-effectiveness.

Despite its many benefits, ultrasound processing also has some challenges, including high equipment cost, limited understanding and experience of the technology, and usage complexity. The positive future of ultrasound processing in the food industry looks promising, with advances in technology and equipment making it more accessible and cost-effective for the food businesses of all sizes.

Frequently asked questions

Q. Advantages of Ultrasound in Food Processing

The main advantages of ultrasound processing in the food industry are improved quality, increased yields, enhanced safety, reduced processing time, and cost-effectiveness.

Q. How does ultrasound processing improves the food quality?

Ultrasound processing can improve food quality by enhancing the texture, flavor, color, and nutritional value of food products. It can also reduce the formation of off-flavors and off-odors.

Q. Is ultrasound for food safe?

Yes, ultrasound processing is safe for food products. It can reduce the risk of contamination and foodborne illnesses by destroying harmful microorganisms.

Q. Ultrasound is costly or cheap?

Yes, ultrasound processing can be cost-effective for businesses in the long run by reducing waste, increasing yields, and improving product quality.

Q. Future of ultrasound processing of foods?

The future of ultrasound processing in the food industry looks promising, with advances in technology and equipment making it more accessible and cost-effective for food businesses of all sizes.

In conclusion, ultrasound processing is a non-thermal processing technique that uses high-frequency sound waves to improve food quality, safety, and shelf life. Its numerous applications in the food industry make it a valuable tool for businesses to improve their products and processes. Despite its challenges, ultrasound processing has the potential to revolutionize the food industry and provide consumers with safer and higher quality food products.

You can follow vishalfoodtech:)